Maintenance

Preventive maintenance pays off

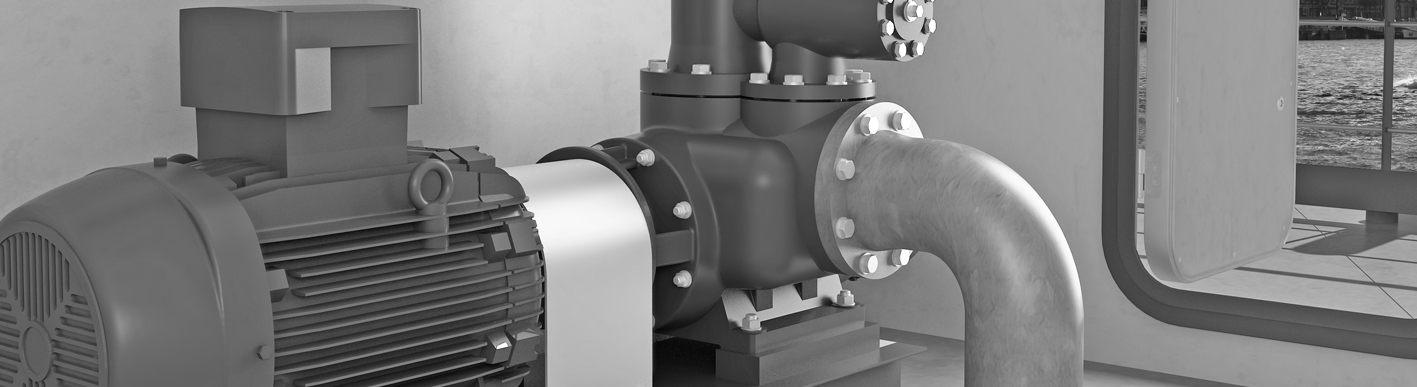

Proper maintenance prevents expensive repairs. Leave your periodic maintenance to us to prevent unnecessary costs.

KAMPERS would be pleased to take care of your twinscrew pumps. If you purchase a maintenance contract for the periodic maintenance of your pumps, it will prove to be worthwhile. Furthermore you can always contact us for advice regarding the daily maintenance of your pumps.

"LBC Tank Terminals Antwerp is completely satisfied with the repair and maintenance services provided by KAMPERS."

Mr.bart Kwick, Planning and Maintenance Coordinator, LCB Tank Terminals Antwerpen.

Preventive Maintenance

Technical developments have greatly improved the possibilities for preventive maintenance over the last years. For twinscrew pumps the most important development is the improvement of vibration measurement. The vibration of the shaft indicates the condition of the bearings and other rotating parts. By monitoring the bearings and replacing them in time, severe consequential damage on screws, casing, shafts and gears can be prevented. Sustainability plays an important role in modern day society.

Extending the life cycle of pumps and pump components forms an integral part of a sustainability policy. However, it does not only save the environment. KAMPERS maintenance can also save a large amount of money on your maintenance budget.

The advantages are:

- Saves costs

- Reconditionings and overhauls can be planned

- Extends the economic lifetime of your pump

- Increases reliability of your pumps

Best practice guidelines for twinscrew pumps:

- Do not let the pump run dry for too long. Running without product is the number 1 cause of pump damage.

- Reduce the speed of the pump if cavitation occurs. A pump that runs slower without cavitating, is more productive than a cavitating pump. Cavitation is the number 2 cause of pump damage.

- The manufacturer has set the safety valve at a certain pressure. Do not change it at random.

- Check the properties of the product you are handling. Is your pump suitable? Think about material, seals and heating.

- Listen and feel. Does the pump sound normal? Is the temperature normal?

- Execute maintenance activities regularly:

- Change the oil in the gear box (check the manual for intervals).

- Make sure that there is enough grease in the bearings, but…

- Not too much! Too much grease causes damage to bearings as often as a lack of grease.

- Last but not least: read the pump manual!